Electroplating

Electroplating is a method of laying a layer of metal on a conductor using the principle of electrolysis.

1.According to different needs, our company provides the following types of plating/p>

(a)Zine Plated :

After Zine Plated , the zinc layer has the advantages of low cost, good corrosion resistance, and good ductility, and can have the advantages of resistance to handling, impact, aesthetics, and storage; therefore, it is used in light industry, instrumentation, electromechanical, agricultural machinery, construction, automotive, and national defense. Widely used in industry

(b)Nickle Plated :

It has good santi-corrosion performance, also has good stability in the temperature environment above 300 ℃, avoids alkaline corrosion in contact with aluminum alloy, neutral salt spray test can reach more than 1000 hours, and has high hardness and decorative Good and other advantages. The baking temperature is low. As long as it is under 400 ℃ for different standing time, different corrosion resistance and wear resistance can be obtained. Therefore, it is also suitable for complex shapes, but the unit price is higher.

(c)Nickle-iron Plated:

Protective alloy coatings not only have higher corrosion resistance than zinc coatings, but also have many advantages such as weldability, paintability and ease of processing.

(d)Phosphorus: It has good adsorption capacity, can be used as the bottom layer of coating, and after the phosphating treatment, the lubricant can not only stabilize the friction coefficient of the parts, but also strengthen the effect of cold forming.;

(e)Chromium Plated:Automatic parts, furniture, and hardware kits are chrome-plated to achieve corrosion resistance.

2.it can be divided into

(a)Rack plating

Put the products on racks. This kind of plating is suitable for those would easy deformation or with large size.

(b)Barrel plating

Put the products need plating into rollers. This kind of plating is suitable for those cannot put on racks limited to shape and size.。

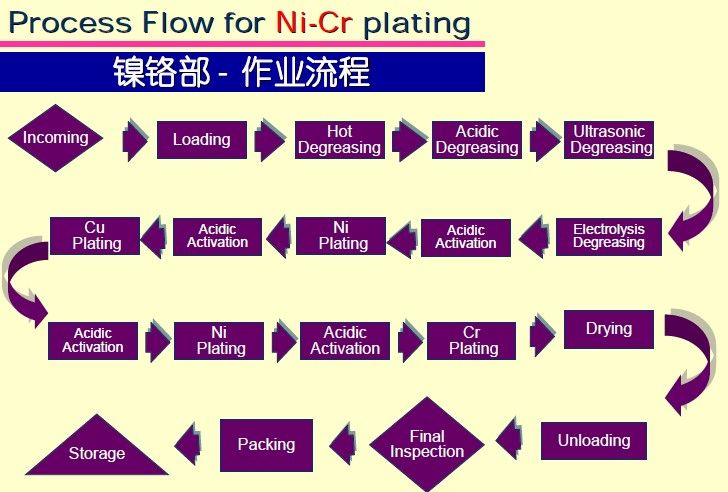

electroplating flow chard: